Dual-Sided Touchscreen TV

Duration: Oct- Dec 2016 & May - July 2017

Role: Engineering Lead / Mechanical Engineer

Design: Matter

As lead and sole hardware engineer, I led the development of a fully-functional demo prototype for a dual-sided touchscreen TV concept featuring motion tracking cameras and 4K cameras on each side for added interaction. Starting with a volume study and collaborating with ID to do concept evaluation and down-selection, I then detailed the architecture for the structure, active components, thermal management system, and cosmetic cladding. Working with a local fabricator, I oversaw the construction and cosmetic finishing of the prototype, which was installed at the client’s office and is still used for demos. End to end the design, fabrication, and bring-up was 12 weeks. After the first delivery, the client came back for a second, improved unit a few months later.

Wearable Audio R&D

Client: Facebook Building 8 (Now Meta Reality Labs)

Duration: October - November 2017

Role: Mechanical Engineer

Meta Reality Labs AR Glasses platform takes advantage of cartilage conduction audio to communicate insights from the onboard cameras to the user without obstructing their hearing with traditional audio paths or vision with heads-up display. As part of the early concept team, I researched and tested bone/cartilage conduction audio, conducted human variation / ergonomic studies, and prototyped glasses-integrated bone/conduction audio systems to demonstrate feasibility and understand the effect of long-term wear and the environment on the user. Our insights led the client to pursue cartilage conduction audio instead of the prevailing bone conduction audio path, which is currently the audio path in the platform and the topic of several patents for Meta. (Meta Project Aria)

Smart Light Switch

Duration: January - March 2017

Role: Lead Mechanical Engineer

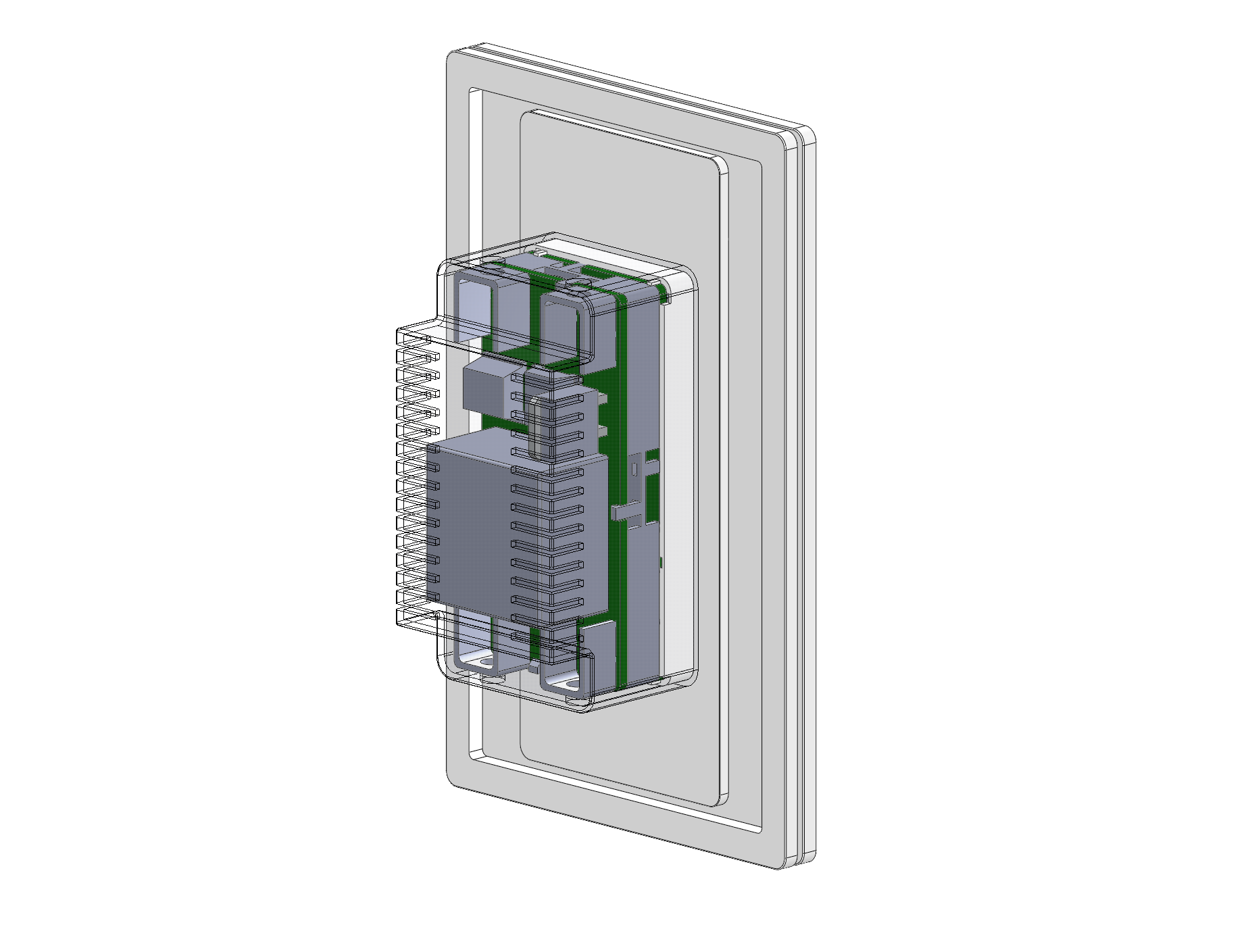

As the lead mechanical engineer developing a smart light switch, I collaborated with ID and EE to design a tightly constrained electrical assembly that integrated sensors behind a dead-fronted exterior surface. Designed to seamlessly fit into any standard switch box, the smart light switch had motion and proximity sensing to learn about patterns of home use. In addition, it featured a microphone array and speaker for voice interaction and also, a cap-slider and tactile button for lighting control. We developed prototypes and a production-intent architecture for the device, delivering a functional, form-factor prototype for demos.

Medical Robotics

Medical Robotics Platform for Endoscopy Procedures (2022)

As an engineering lead and mechanical engineer working for a medical robotics company, I designed and developed a proof of concept prototype for the robotics platform including architecture design, mechanism design, electromechanical integration, drivetrain design, and end-effector design.

Next-Generation Controllers for Laparoscopic Surgery (2016)

As a mechanical engineer working for a surgical robotics company, I designed and developed new concept controllers for laparoscopic surgery. Responsible for concept generation, user ergonomics, prototype design, and user testing.

Medical Robotics End-Effector for Needle Guided Surgery (2022)

As a mechanical engineer working for a medical robotics company, I developed concepts for an ultrasound attachment to allow for robotically assisted needle guided surgery.

Meraki Z3 Stand & MR30H Security Mount

Client: Cisco Meraki

Duration: March - April 2017

Role: Engineering Lead / Industrial Design

Working for Meraki, I designed and developed three accessories for their router products, two of which are on the market today. The first is an elevated stand for one series of router that allowed the device to be more easily installed without permanent fixtures. For this project, I developed many versions in sketch and mockup forms to evaluation. The second is a tamper-proof cover for cabling that prevents hotel guests from having access to the router ports. For this project, I architected and designed the production parts for injection molding. The third is a small, stable stand for Meraki’s portable travel router that allows users to easily setup in new spaces. For this product, I designed, prototyped, and developed the manufacturable design for die-casting and insert molding. (Z3 Stand | MR30H Security Mount)

Future of First Response

Client: Pacific Northwest National Lab & DHS

Duration: May - August 2015

Role: Strategist / Mechanical Prototyper

Design: Continuum

The Future of First Response is a vision for the tools, clothing, technology, and support systems first responders will need in 10-15 years. The goal of the program was to bring together key players in the first responder community, industry, and government, to define that future vision, then develop those products and systems. Our goal was to make first responders safer and more effective by taking care of the "stuff" and enabling them to focus on their craft. A key learning was that technology could not rival human experience and expertise, when it came to making quick calls in emergency situations. Our solutions had to support that individual with experience and expertise, not try to replace them

While interning at Continuum, I served as a strategist and prototyper for this project. As a strategist, I collaborated in ideation sessions to design and evaluate concepts for new technology that could make first responders safer and more effective. Additionally, I setup user research sessions where first responders could user test the initial prototypes in mock-up scenarios to learn more about the needed interactions. As the prototyper for the project, I was responsible for the creation of looks-like prototypes representative of the technology concept. I created multiple iterations for each of the technology concepts driving towards the final looks-like prototypes used for concept demo sessions.

Additional Documentation: DHS: Next Generation First Responder Core77 Design Awards Page

LG Scroll and Wallpaper TV

Client: LG

Duration: May - August 2015

Role: Mechanical Engineer

Design: Continuum

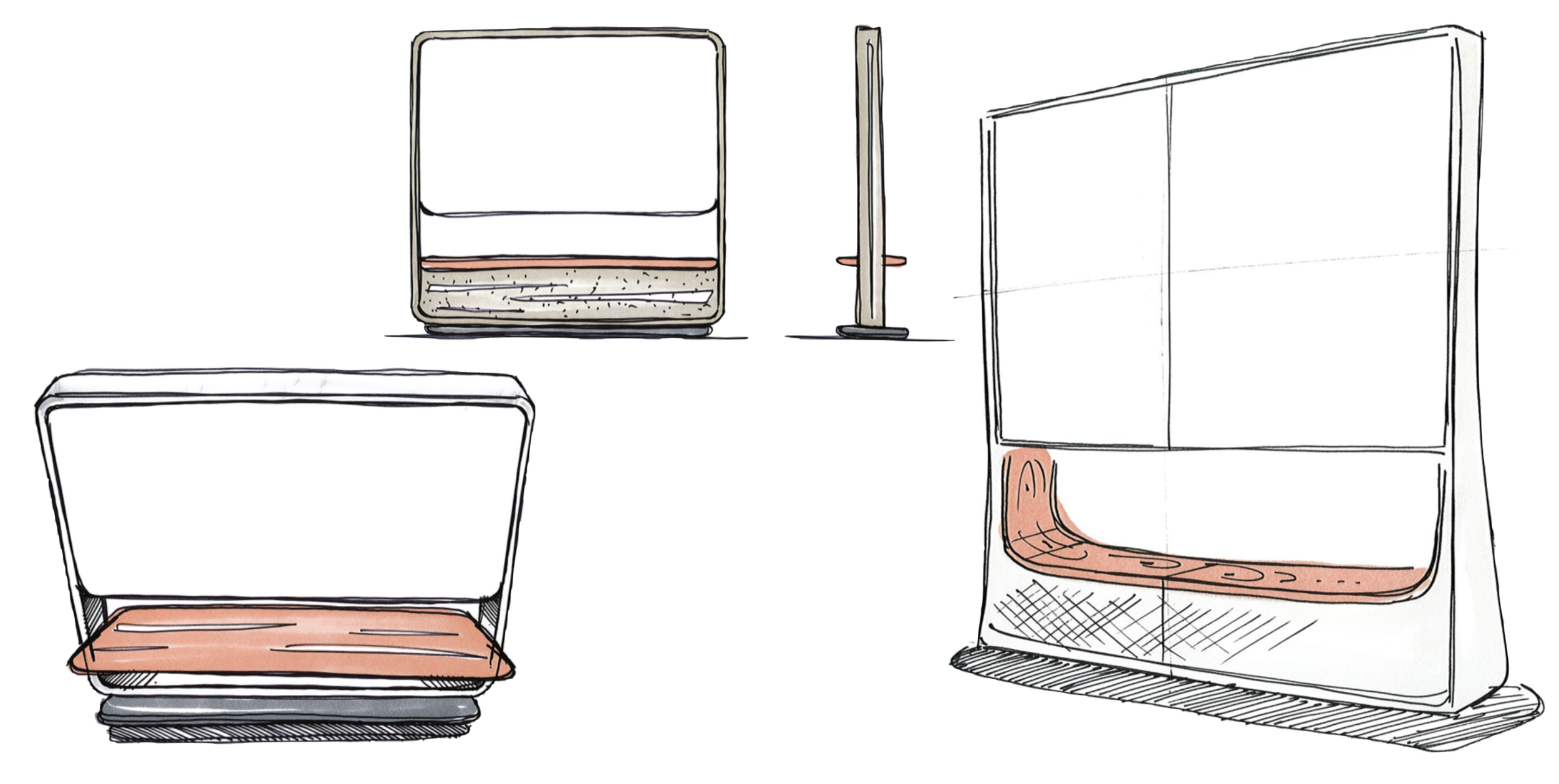

While interning at Continuum, I worked as a mechanical engineer collaborating with a team of industrial designers on future concepts for flexible OLED TVs. On the project, I contributed to concept generation and was responsible for concept feasibility evaluation, volume studies, basic mechanical architectures, and mechanism design. Our team presented three concepts and mockup prototypes to the client. In the years since concluding the project, two of the concept TVs have been launched and showcased at CES, each receiving a Best of CES Innovation Award. (LG Wallpaper | LG Scroll)